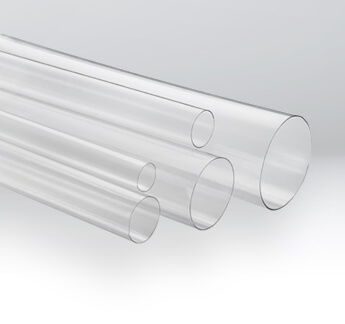

Several sizes of clear plastic round tubes are stocked, but custom lengths can be extruded and cut to the desired lengths. Many styles of caps and plugs can be added to transform the clear plastic tube into a container. Or, the clear round tube can be converted to a container by permanently sealing one end. The choices are a rigid bottom or a flexible bottom, and both styles have a variety of caps and plugs to complete the package.

It is best to select a plastic tube container size before deciding on a cap or plug, as not all caps and plugs fit all tube diameters.

What is the difference in rigid and flexible bottom containers?

VisiPak packaging tubes can be outfitted with a number of different bottoms to transform them into containers. The most commonly used bottoms are clear plastic PermaSeal plugs that are sealed into the tube to create our line of tube containers. However, many of our tops can also function as bottoms and we have the ability to manufacture custom bottoms to meet your exact needs. Do you want to see all of the additional options included with our containers? Please visit our main plastic tube containers page.

Rigid Bottoms

The rigid bottom insert used in our containers are ideal for most retail packaging applications as they feature excellent clarity, light weight and are approved materials for packaging by all major retailers.

- Recyclable & FDA approved

- Excellent clarity and light weight

- Made from approved PETG and

propionate materials

Flexible Bottoms

Our flexible bottom inserts are ideal for packaging heavy or sharp items like drill bits or cutting tools. The bottoms possess elastic properties as well as a longer skirt that adds strength to the seal of the container.

- Flexible bottoms absorb weight and stress

- Material will not split or crack under pressure

- Flexible bottom inserts record the highest

impact strength in the industry

Other Options

While the majority of the packaging containers we produce utilize our clear plastic bottom inserts, many standard and customized options exist including completely custom dip or injection molded closures.

- Poly plugs & caps with flat bottoms

- Vinyl caps for tubes that don't need

to stand - Custom molded bottoms like the

ones shown above

Features of Clear Tube Packaging

Clear plastic tube packaging has a number of features that make it advantageous over many other form of packaging...especially printed cardboard packaging.

Low Cost

Not only is the clear plastic extrusion process very cost effective, but it eliminates the need for expensive graphics to be designed and applied to packages.

Customization

Clear tubes can still be customized with direct printing or simple and inexpensive labels. For larger volume applications, custom molded lids are an option.

Clear Display of Product

With clear plastic tube packaging, customers can get a 360° view of the actual product they are buying.

Protection

Plastic tube containers are not subject to water or moisture and tend to resist bending or denting much better than cardboard.

Our Work

VisiPak's clear plastic containers are used by a wide variety of companies for packaging all types of cylindrical and loose fill products. They are ideal for applications where one desires both a package and container for its product.

Jelly Belly Candy

Watanut Cookies

Eviroscent

Starbucks

Plus Plus Toys

Pennington

Zero Friction

Elizabeth Arden

Tube Containers FAQ

- What is a tube container?

-

A VisiPak tube container is an extruded clear plastic cylinder that is affixed with either a rigid, flexible or crimped end. This open ended tubular container can be outfitted with a number of different caps, plugs and inserts to convert it into a functional container.

- What is the primary advantage of VisiPak tube packaging?

-

The primary advantage of VisiPak's clear plastic containers over most other round containers is that they do not require tooling to produce. We have a wide variety of shapes and sizes that can be extruded in virtually any length...making it possible to offer an unlimited number of different sizes with no tooling or design charges.

- Is tube packaging sustainable?

-

While virtually all of the plastics that we use are recyclable, our new RecylcaPak tubes utilize 100% clear PET, the most recyclable grade of clear plastic on the market.