Part Trays

With a greater move towards automation and robotics in today’s modern manufacturing operations, the need for material handling and parts trays is greater than ever. Parts trays protect sensitive parts and align them for automated pickers. They also ensure exact counts for automated systems and can function as shipping trays as well.

Custom Design

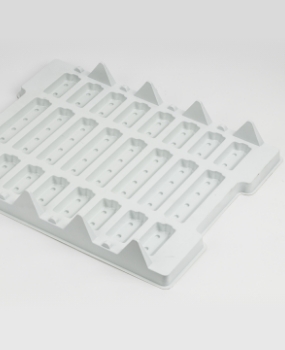

Most packaging material handling and parts trays are custom designed and manufactured to your exact specifications with the most commonly used materials being PVC, PETG and PET. Shown here is a clear tray designed to hold small components.

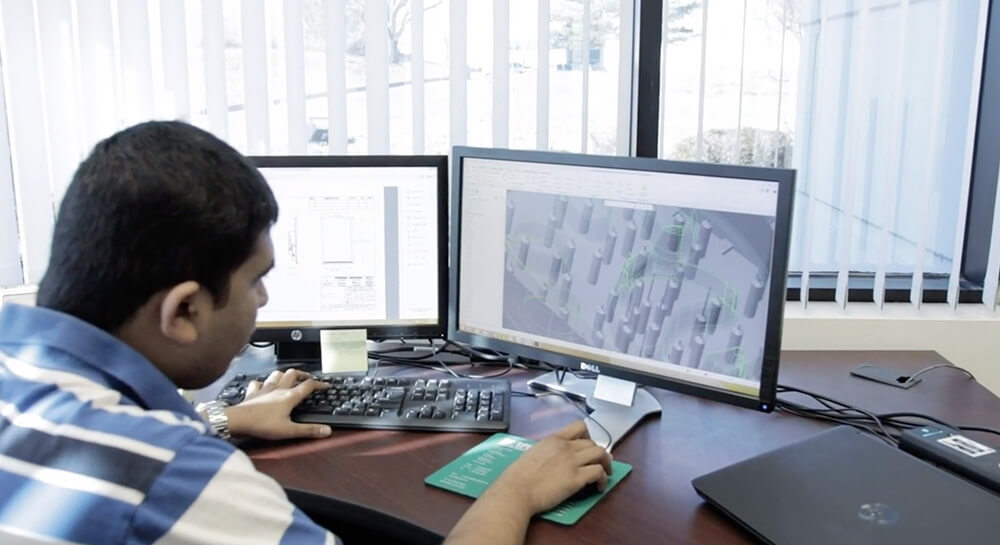

Rapid Prototyping

With extensive experience designing thermoformed shipping trays and comprehensive prototyping capabilities, our design team can quickly turn your conceptual designs into tangible prototypes, so you can get your product to market faster and more cost-effectively.

- 3D and 2D Computer Aided Design Software

- Start of the Art 3D Laser Scanners

- 3D MicroScribe Digitizing Equipment

- CNC Mold Milling Machine

- 3D Printers for Precise Model & Sample Generation

Exact Counts in Exact Positions

One of the primary benefits of using parts trays - whether they are used in process or as shipping trays - is that they require an exact count of each product to be packaged. But that’s not all. Because the products are stored in the same manner each way, automated picking systems can be employed.

Manufacturing

Once your shipping tray is designed, you can rest assured that it will be manufactured with quality and efficiency in our ISO 9001:2015 Certified facility featuring high-speed inline thermoformers.

- ISO 9001:2015 Certified Facility

- Cleanroom Manufacturing Options

- Extensive Production Capacity

- Consistent Quality

- U.S. Based Production

Custom Material Handling & Parts Tray Gallery

Valve Tray

Precision Parts Tray

Industrial Packaging Tray

Hinged Shipping Tray

Electrical Components Tray

Magnet Tray

Electrical Components Tray

PCB Tray

Wafer Fab Tray with Lid

Memory Card Tray

In Process Tray