ESD Trays

VisiPak specializes in the design and manufacturing of custom ESD Trays including anti-static, static dissipative and conductive options (electrostatic discharge). These ESD safe trays are typically used for the packaging, shipping and storing of small electronic parts like PCBs, circuit boards, and other components.

Precision Designs

Armed with some of the world’s most advanced thermoforming machines and an engineering team skilled in producing high-precision trays, VisiPak has become a leading source for ESD trays requiring complex designs, very tight tolerances, integrated markings and more.

We also understand the need to maximize product protection while creating trays that ship and store electronic components in the most cost-effective manner possible. Our team is skilled in designing trays with the needed structural integrity, nesting capabilities and stacking features to accomplish these goals.

In House Material Testing

Our in-house team employs specially developed procedures to test both received materials and finished parts to ensure compliance. ESD tray material options include conductive, static dissipative and anti-static.

Our Work

The combination of all of this talent and technology has allowed VisiPak to create some of the most functional and innovative ESD trays on the market often achieving the precision detail that many assume can only be achieved with injection molding.

Tight Tolerances

The client was experiencing difficulty with its thermoformed trays being unable to perform consistently in its robotic pick-and-place packaging process. The placement of the extremely sensitive parts required a cavity tolerance of .005”, an incredibly tight tolerance, which even VisiPak engineers initially questioned as being possible.

Precision PCB Tray with Dividers

For this PCB tray, VisiPak’s engineers utilized a special static dissipative material that not only complied with ESD concerns, but featured the material distribution characteristics needed to form the extremely thin fins. VisiPak’s ability to use its expertise in tool design, precision thermoforming, and materials allowed it to deliver a solution for this extremely demanding solution.

Protective Trays

For this global manufacturer of computer printers, our team developed a number of thermoformed covers, inserts and a small custom tray to help protect components within the printer during shipment. The small ESD tray was designed to protect inks and be sealed into a foil pouch – a process that required the tray to have an extremely smooth die cut edge that would work in their high-speed automated production line.

ESD Clamshell Packages

In addition to manufacturing ESD trays, VisiPak is also one of the leading manufacturers of thermoformed clamshell packaging. For this particular clamshell, we worked with our client to develop a custom clamshell package using anti-static material that would protect this memory card during shipping.

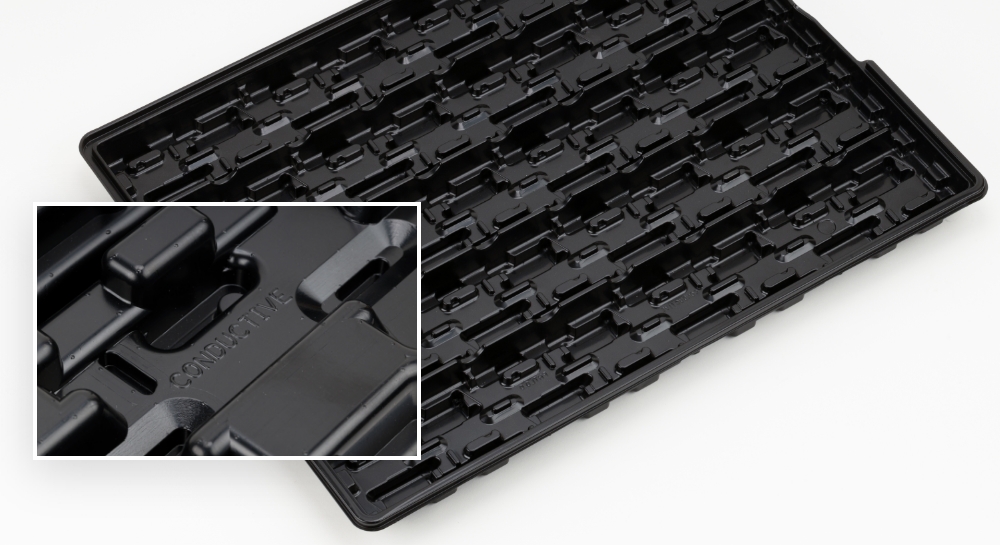

Wafer Fab Manufacturer

Product: Condusctive Tray

Application: Electronics

ESD Tray Gallery

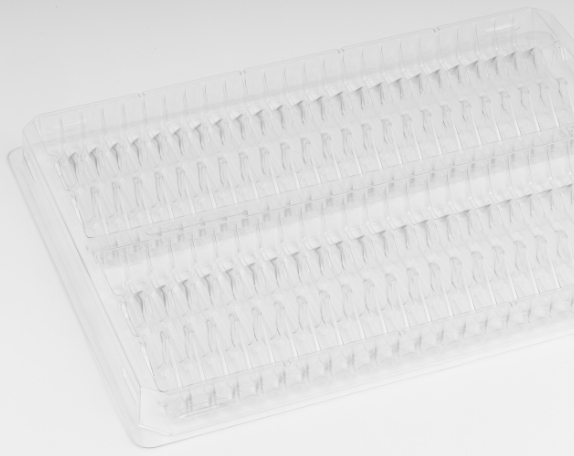

Semiconductor Manufacturer

Product: Tray

Application: Electronics

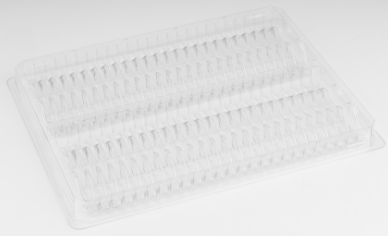

Printed Circuit Board Fabricator

Product: PCB Tray

Application: Electronics

Ready to Get Started?

Request Quote

and/or Samples

Contact sales for volume pricing and

access to free samples for testing and

prototyping.

Contact a

Packaging Specialist

For help finding the best package for

your application or creating one that

is customized to your specific needs.

Shop Our

Online Store

For immediate access to our stock

packaging tubes, clamshells,

containers, caps and more.