While "diamonds are a girl's best friend," the team at Element 6 was dealing with some unfriendly packaging challenges related to their synthetic diamonds. Sold throughout the world for primarily industrial applications, the company needed a unique, multi-functional package.

The Challenges

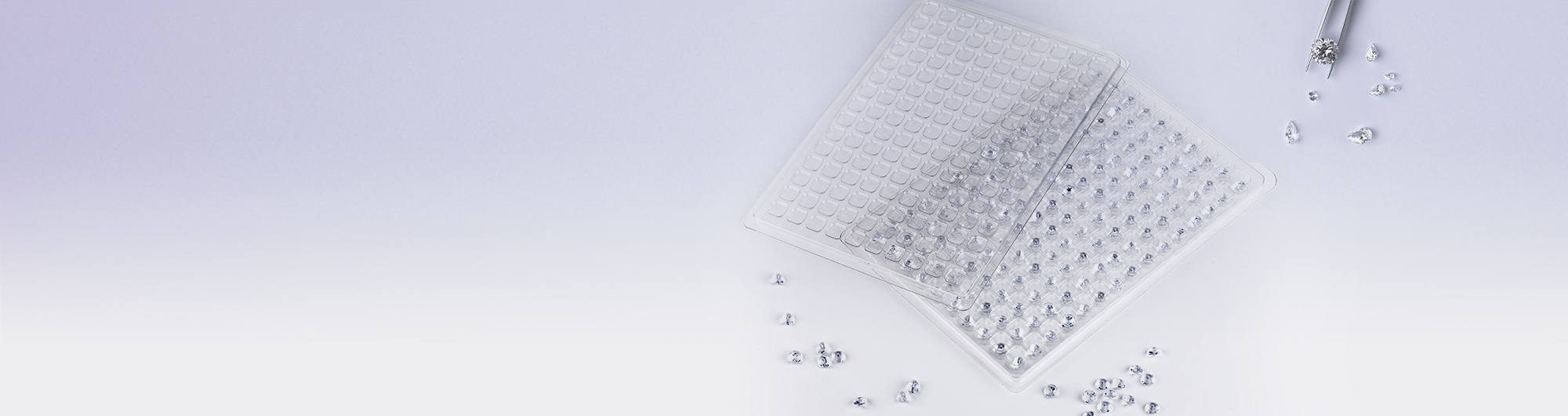

Given the high value of each individual diamond, Element 6 wanted a plastic packaging tray with the following characteristics.

- Embossed numbers in each cavity of a 100-count tray

- A friction fit lid to further protect and keep the diamonds organized during shipment

- A durable, ultra clean, precision thermoformed tray

Embossed Cavities

While making numbered shipping trays is a skill that VisiPak has virtually perfected, the embossing process always adds an element of complexity to the design.

The embossing process stretches the material...creating additional stress that is not present in most packaging trays.

To combat this, engineers had to find the right combination of material thickness and heat to develop a design that would accommodate both the embossing process and a friction fit lid while still achieving Element 6's durability and cost goals.

Friction Fit Lid

To ensure that the diamonds would not become displaced from their cavities during shipment, the VisiPak team designed a friction fit lid that would effectively hold all of the diamonds in place.

Since many customers do not use all 100 diamonds at one time, developing a complete package that could be opened and re-sealed was very important.

Durability, Precision & Cleanliness

Since many diamonds were going to be used in highly sensitive industries like semiconductor and electronics manufacturing, special care needed to be taken to ensure their durability, precision and cleanliness.

- Durability was designed into the tray

- Trays were manufactured on precision machines in a clean environment

- VisiPak had the capacity to meet volume demands now and in the future