How To Info

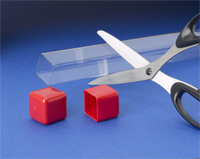

How to Cut a Tube

Custom orders or production runs of clear plastic tubing can be cut to a specified length so that each piece is the same size. Special cutting equipment is employed during the actual manufacturing process; it is not a separate process. This cutting equipment helps to make very clean cuts for the ends of each clear plastic tube.

However, VisiPak stocks 4-foot tubing which is often purchased because of the need for very low volumes of various length tubes. The 4-foot clear tubes are sold so that each piece can be cut down to the required size, multiple sizes, as needed. There are a number of ways to manually cut clear plastic tubing, and often a simple pair of scissors or a paper cutter is all that is required. When using a paper cutter, it is helpful to insert an item, such as a wooden dowel or plastic pipe, inside the tubing to hold the clear tube firmly. It is best when the item inserted fits snugly inside the tube. This process works best when you only need to cut a small volume of tubes. For larger diameter tubes, we advise making a cut at the opening, downward and then spiraling around giving space for the movement of the scissors.

When the project is larger and many tubes need to be cut, an electric mitre saw or chop saw is useful. For the cleanest cut, it is best to use a masonary blade or plastic tubing blade on the saw.

Clamshell Measuring for Fit

No matter if you need custom or stock clamshells, you need to know about size. To configure how your product will fit in the cavity, to understand the area surrounding the cavity, to provide features for display – these are features to be aware of before purchasing clamshell packaging.

While the most critical area is the cavity, if the product is for a retail environment there needs to be room for the marketing logo and message, specific features, instructions, restrictions and more. The size of graphic Insert cards needs to be considered. Additionally, in retail some clamshells will be displayed on pegboard hooks, others standing on shelves.

How to Determine the Length of a Hang Tube

Hang tubes are manufactured in two steps. First the tube is extruded, then one end of the tube is pressed closed, creating a closed-ended tube. Based on this, would you consider the length of the tube as the usable inside space or the actual physical length of the entire piece? Of course, this is a critical consideration when placing an order. If you have any questions, we are always ready to provide answers to help you get the best fit for your project.

How to Seal a Clamshell

VisiPak recommends a handheld clamshell sealer for low volume applications. A dual heat, electric powered handheld clamshell sealer creates a 1/2″ x 1/4″ spot seal and works with our stock PVC clamshell line. Economically priced, the sealer is ideal for sealing clamshells to prevent pilferage or product damage and is supplied with a high and low temperature control switch with power light and proportional temperature control system.

Watch the video or visit our page on Clamshell Sealing Options.