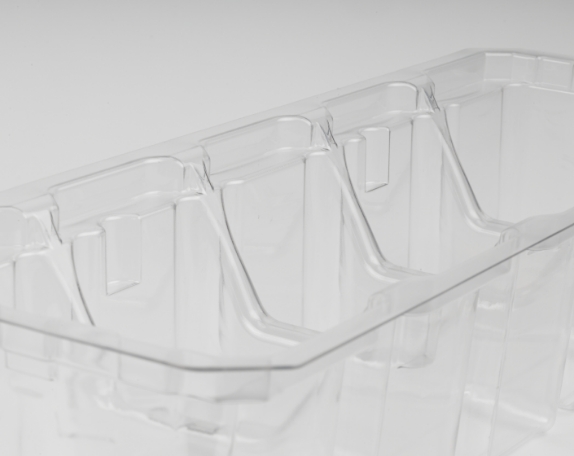

Unique Tray Design

Our client is a leading producer of fluid testing systems laboratories used by laboratories throughout the world.

The Challenge

The supplier who was manufacturing our client’s thermoformed trays was not able to consistently maintain the stringent quality requirements needed for the trays to process in its automated feeding and sealing equipment. This was causing problems with the equipment and reducing the efficiency of the packaging line.

The Solution

The first step in identifying the solution was identifying the problem. VisiPak’s engineers identified that the tray’s cavities featured a very deep draw which required a starting thickness of material that very few in-line thermoforming machines can successfully process.

With the aid of VisiPak’s more technologically-advanced equipment, our team designed a highly unique thermoforming process and built custom tooling that was able to consistently produce the deep draw thermoformed trays.

The Result

VisiPak has met our client’s tight quality specifications for many years now and the increased throughput and efficiency in the automated feeding and sealing process has led to significant cost savings.

Ready to Get Started?

Request Quote

and/or Samples

Contact sales for volume pricing and

access to free samples for testing and

prototyping.

Contact a

Packaging Specialist

For help finding the best package for

your application or creating one that

is customized to your specific needs.

Shop Our

Online Store

For immediate access to our stock

packaging tubes, clamshells,

containers, caps and more.