Industrial Packaging Trays

With the increased adoption of automated pick-and-place robots, the ongoing focus on continual quality improvement and the need for more sustainable packaging, the market for precision thermoformed trays in the industrial market has never been greater. See why companies all across the world are choosing VisiPak for their packaging and material handling trays.

Our Ability to Design for Automation

Flourishing in today’s competitive marketplace typically requires a fair amount of automation. The VisiPak team has been at the forefront of developing trays that work in automated environments.

- We understand the requirements of parts feeding in automation, denesting, and close tolerance flanges.

-

We specialize in creating trays with tight-tolerance cavities that provide the precise product fit required in many automated pick-and-place processes.

We offer both silicone-coated and internal denest material options to ensure consistent performance in automated dispensing processes.

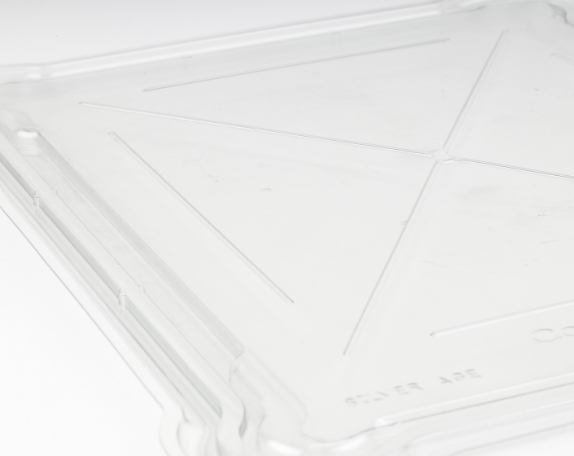

Capable of Precision Thermoforming

Whether it relates to automation or the need to minimize movement of parts during transit, producing trays and packages with tight cavity tolerances that yield a precise product fit have become more essential than ever.

Our team not only utilizes some of the most sophisticated thermoforming equipment in the industry, but our ISO certified processes and decades of experience makes us an ideal partner for developing all types of industrial packaging solutions.

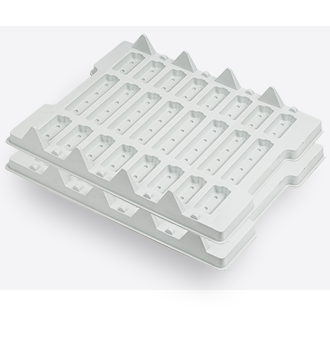

Rotate-to-Stack Design

Our innovative “Rotate-to-Stack” designs combine nesting designs that save space during the shipping process, but rotate and stack to provide clearance between trays when product is stacked in the cavities.

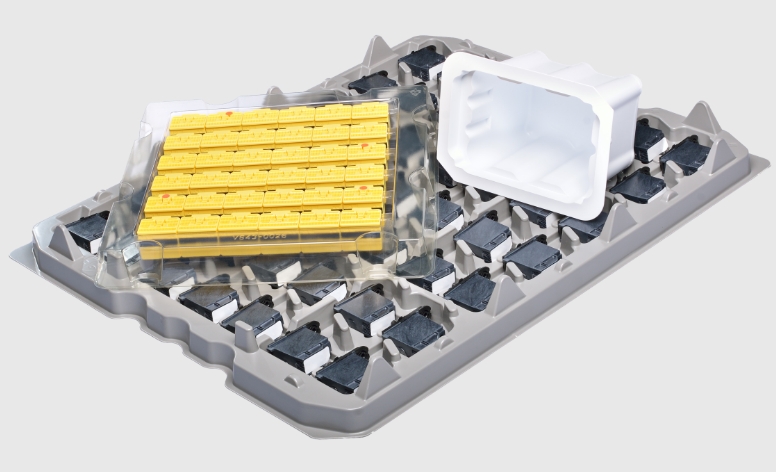

Intricate Designs

VisiPak’s extensive experience in designing and forming products with intricate and complex shapes is second-to-none. This “parts tray” features 40 precision cavities, stacking features and is made from a conductive material.

Extremely Tight Tolerances

To help this client’s tray perform consistently in its robotic pick-and-place packaging process, our engineers successfully designed and produced a tray with a cavity tolerance of .005” that held the near-exact placement of the extremely sensitive parts.

Protective Shields

To help one of the world’s leading manufacturers of business equipment, our team designed and produced a series of intricate, lightweight shields to protect computer printers during shipment.

Ready to Get Started?

Request Quote

and/or Samples

Contact sales for volume pricing and

access to free samples for testing and

prototyping.

Contact a

Packaging Specialist

For help finding the best package for

your application or creating one that

is customized to your specific needs.

Shop Our

Online Store

For immediate access to our stock

packaging tubes, clamshells,

containers, caps and more.